Pure Polyurea

Ultimate Linings is the leading supplier of polyurea coatings.

Ultimate Linings provide complete coating solutions and superior product support. From the polyurea formulation to the final application, UL has the expertise to guide the customer to a successful coating.

With many polyurea formulations in the UL portfolio, we are confident we have the right solution for your high-performance coating requirements. Our range of pure polyurea is designed for water tanks, roofing, high-wear & high-impact areas, and so much more.

The benefits of Pure Polyurea include:

Solvent-free and emits no volatile organic compounds (VOC)

Fast tack-free and gel times, allowing a quick return to service

High-wear and impact resistance

High elongation properties

Chemical resistant formulations

Seamless water-tight seal

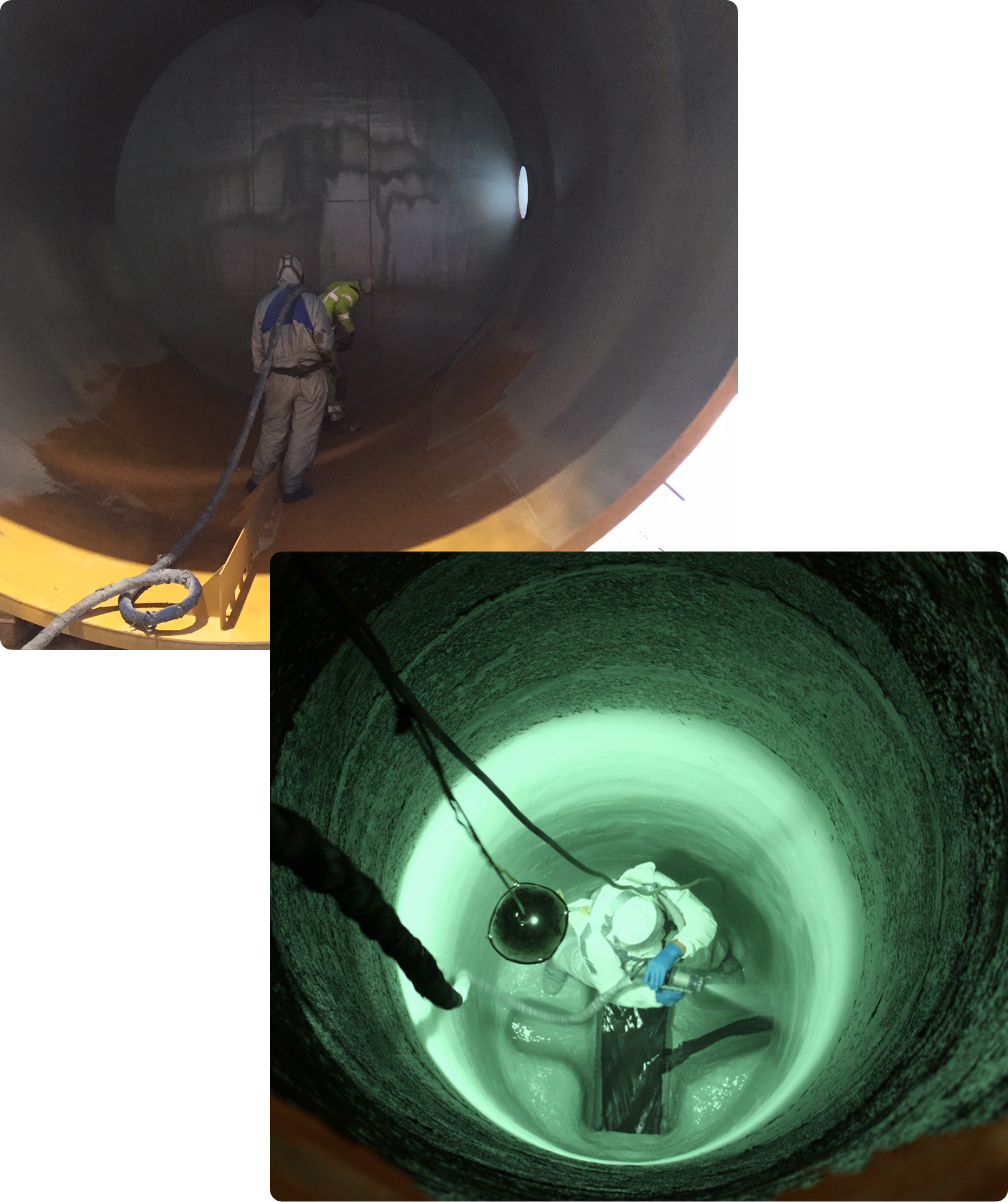

High-pressure Pure Polyurea Systems

The most popular Ultimate Linings polyurea coatings are applied via high-pressure machines, such as the Graco Reactor 3 proportioner. These systems are suited to high-volume and continuous coating applications. Typical high-pressure polyurea applications include tank lining, large industrial flooring applications, waterproofing, and manufacturing facilities.

Low-pressure Pure Polyurea Systems

Roll-applied polyurea coatings generally have a longer gel time, allowing the applicator to apply polyurea to a large surface area without tacking off too early. The slower gel time allows the polyurea to be spread evenly and self-level. Roll-applied polyureas are often used as an intermediate coating for waterproofing and areas requiring a flat finish.

Castable polyureas also have a longer gel time, allowing the coating to flow and fill the voids and bug holes. Castable materials are often used for applications where the polyurea needs to fill tight areas and voids, such as concrete repairs.

Cartridge systems are utilized for low-volume and entry-level applications. Low-volume applications include outbound repairs, smaller industrial applications, and occasional truck-bed lining. The advantages of the cartridge system are low start-up costs, minimal equipment maintenance, and minimal material waste. Polyurea cartridge systems have the fast-dry times associated with high-pressure systems, which is an additional advantage over roll-applied and castable systems.

Work With Us

Have questions about polyurea coatings?

We Can Help

Our experts are open to understanding your unique situation.

Fill Out Form

Contact us about your company’s industrial coating needs.

Let’s Talk

We will reach out to find a time you can talk with your coatings expert.