Polyurea Chemistry

Ultimate Linings provide superior coating systems, first-class technical support and customer service.

Home » Polyurea Science » Polyurea Chemistry

Overview of Polyurea

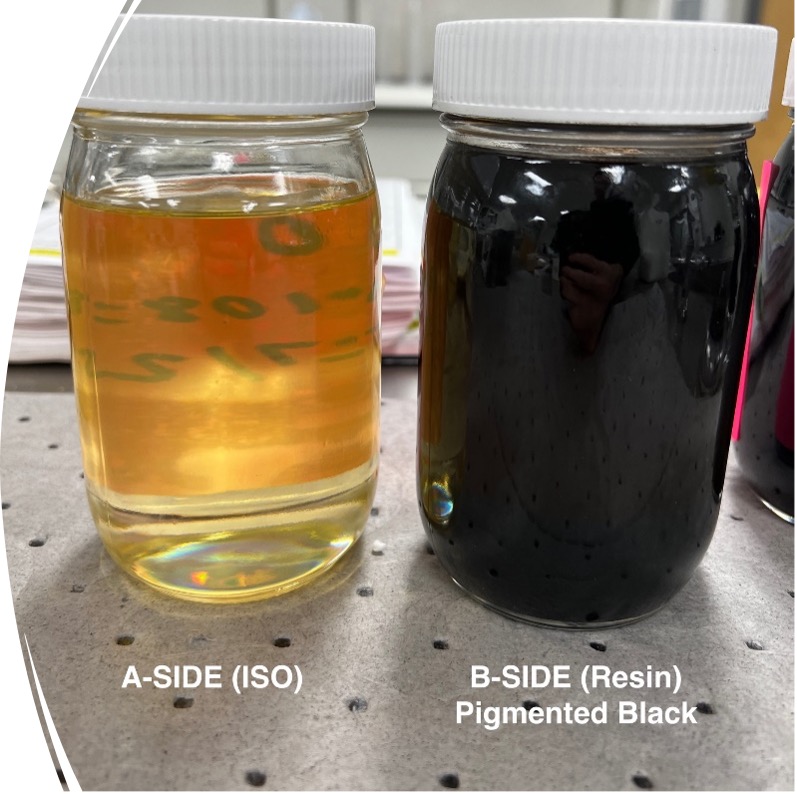

Polyurea coatings are comprised of two basic components: a base and a hardener. They are derived from the chemical reaction of isocyanate and amine resin combined. This reaction typically occurs within a few seconds, so polyurea is quickly and expertly applied using state-of-the-art technology. Polyurea has an industry-leading tensile strength, making it one of the most robust protective materials on the market.

In the right environment and with proper maintenance, polyurea can last over 30 years before it needs touching up, repairs, or replacement.

Polyurea Chemistry

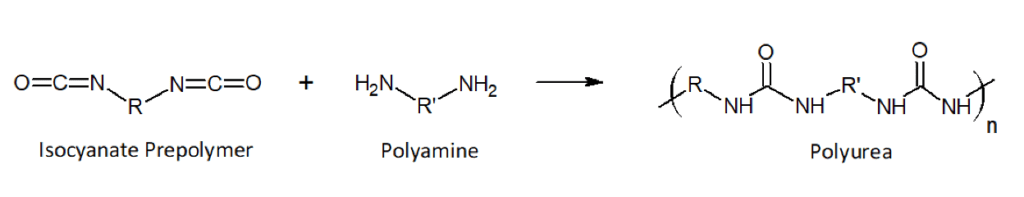

Polyureas are reaction products of isocyanates and amines. These resin systems often compete with polyurethanes in similar coating applications. Like urethanes, they exhibit high flexibility, durability, and chemical resistance, which are superior to most polyurethanes. The main difference between these two technologies is that amine terminated (-NH2) resins are used rather than hydroxyl-terminated (-OH) resins. The reaction of the amines with isocyanates results in the formation of urea linkages (-NH-CO-NH-). The chemical structure of these polymers is given below.

Polyurea’s Strong Molecular Bond Advantages

Highly Durable and Flexible

Polyurea is a lot stronger than traditional coating materials like epoxy and polyurethane. It provides unmatched flexibility, can withstand high and low-temperature variations, and can be applied year-round regardless of weather conditions. Polyurea also boasts high impact, chemical resistance, and abrasion resistance.

Easy to Clean and Maintain

When fully cured, polyurea provides a smooth, flexible, yet durable, solid surface that’s easy to clean and maintain. Polyurea is a low-maintenance protective coating that can withstand sanitization and power washing techniques, making it ideal in food manufacturing and healthcare facilities.

Consistent Long-Lasting Results

With proper maintenance and regular cleaning a polyurea coating can last 30 years or more before needing repairs or replacement.

Excellent Chemical Resistance

Polyurea coatings provide a fast-curing, durable, and flexible protective barrier that prevents water damage and harmful chemicals from destroying virtually any structure. Polyurea is also resistant to petroleum-based and caustic chemicals.

Strong Waterproofing Capabilities

One of the main applications of polyurea is for waterproofing a wide range of structures, including concrete flooring in garages, roofing systems, balconies, terraces, parking garages, wastewater facilities, etc. Polyurea coatings are also suitable for waterproofing and protecting polyurethane foam.

Environmentally Friendly

Polyurea is 100% solids with no solvents or VOCs, which makes it environmentally friendly. Polyurea is perfectly safe for the environment and poses no health risks for humans or wildlife during or post-application.

Easy Application and Rapid Curing

Polyurea is evenly applied using a specialized plural component spray system. Once the liquid has been sprayed onto the surface, the polyurea cures within seconds. This minimizes business downtime and allows the structure to return to use much faster than other protective waterproofing coatings on the market.

We are always happy to hear about your unique situation so we can help you determine the ideal polyurea protective coating solution to extend the life of your investments and enhance the products you offer your customers. Fill out our contact form and we will be in touch to learn about your business and how Ultimate Linings can help.