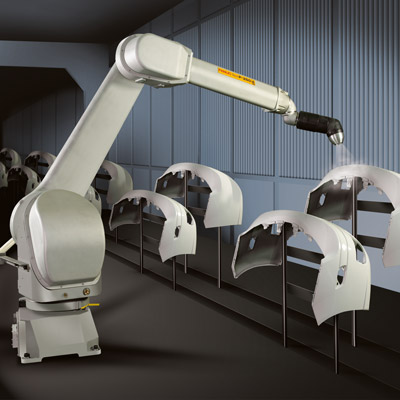

More and more manufacturers are turning to robotics-driven, automated polyurea-application systems to coat and protect their products. For larger companies with multiple stations applying several coatings to numerous products, automation may make sense and offers a convincingly strong ROI.

Ultimate Linings can help you transition from labor-intensive manual spray applications to an automated system—or walk you through the advantages of automation early in your operation’s start-up—as well as facilitate the integration of robotic solutions to increase your production capacity and maximize efficiency.

It’s all part of our unwavering commitment to deliver value-added support and expertise to meet customer challenges head-on. We make good on this promise with a level of industry experience and engineering know-how that’s unparalleled. Our capabilities in polyurea span from initial customer consultation and chemistry development to equipment installation and system commissioning, plus they include superior in-field service, parts availability and on-call support when you need it.

Start-to-finish project expertise

When it comes to automated coating processes, Ultimate Linings engineers, manages and installs the complete system. That’s true whether the project is a retrofit of an existing application process, or a new system designed to satisfy a ramp-up in your production capacity.

We partner with trusted integrators—companies that design and program the robots—to set up these machines and related systems. We’ve been working with leading robotics integrators for more than 20 years and rely on their expertise. Our focus, however, remains on our customer: Ultimate Linings serves as management lead on the project, responsible for equipment and tank requirements, all plumbing (pump and pipe sizes and hose routing), and polyurea flow capacities. If it falls on the fluid and chemical side, we handle it.

During installation and robotics testing, our experienced field techs—several with over 25 years on the job—remain on-site, supporting the customer and integrator at every step and act as an intermediary between them.

When it comes to polyurea formulations and the feed systems to deliver and apply them—automated or manual—no one knows the technology and processes better. Start to finish, you can rely on Ultimate Linings.

Key Robotics Insight: Ultimate Linings is in the final phases of installing a Fanuc robotics spray system in our Nashville, TN, HQ. This sizable investment in technology will allow us to create production pathways in-house and develop tailored programming for customers pursuing robotics systems. Chris Mellin, our Senior Director Technical Services, is Fanuc-trained and certified in automated robotic spray applications.